PBE Expert Inc, we Process, Build, Engineer

Services d’experts-conseils

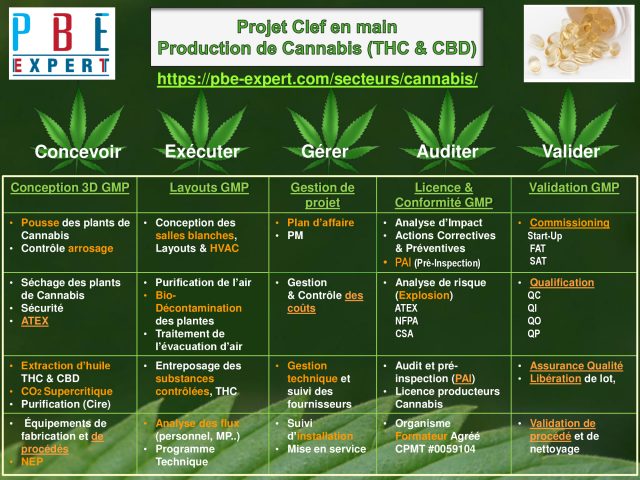

PBE Expert Inc, offre des services en ingénierie des procédés, validation, layout, efficacité énergétique et gestion de projet dans diverses industries.

PBE Expert Inc, we Process, Build, Engineer.

Votre partenaire en génie des procédés et en désinfection COVID, met à votre service une expertise de +25 ans sur +200 projets conformes.

Expert MAPAQ & Santé Canada.

Notre Equipe

Vous recherchez un partenaire en ingénierie des procédés, utilités propres, gestion de projet, NEP, layout, conformité, validation, AQ, Audit PAI, calibration ou efficacité énergétique?

Actualité

Activités récentes

Novembre 2017

Étudiants Polytechnique chez PBE

ILS NOUS ONT FAIT CONFIANCE

Clients

Bureau

CANADA

Pour toute information commerciale, de partenariat et marketing avec PBE Expert Inc

Nous sommes aussi au :